Best performance for your applications

Thanks to our many years of experience with servo motors and motor elements, we can offer you optimized solutions for your application. No matter what requirements you have for our servo motors or which customized motor elements you need for your high-speed and specialty drive system - we will get the most out of your machine.

Your benefits at a glance

- Top reliability

- High overload capacity

- High flexibility

Overview motor solutions

Synchronous servo motors

Check out the different KEBA servo motor series, and you will find exactly the right motor for your machine. Our compact synchronous servo motors, either with a high power density design or as a traditional distributed coil design, are ideal for high-end servo applications.

Your benefits

- High performance density and strong dynamics

- Very low cogging torque

- Very robust

- Energy-efficient

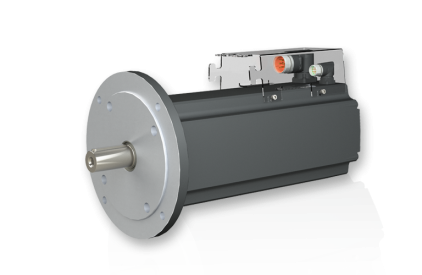

Asynchronous servo motors

Our compact asynchronous servo motor series with high performance density is perfect for complex applications in machine manufacturing. Various cooling concepts and many coil distributions options allow customization as required for the servo controller.

The asynchronous motor series DA completes the upper end of the performance range of the established series LSN, LSP and LST and is available in both air-cooled and water-cooled configurations.

Your benefits

- High flexibility

- High speed control ranges

- High performance range

- M₀ of 33 to 3.024 Nm

- 6 axle heights (100, 132, 160, 180, 225, 280)

- Water-cooled or force-ventilated designs

- Guide-shoe and other options available

- Reinforced bearings, electricity-insulated bearings

Motor elements

Customized synchronous motor elements by KEBA are used everywhere in the world where applications require high rotation speeds or where the applications exhibit the corresponding installation environments. More than 40 years of experience and more than 400,000 motors running enable us to offer our customers a quick conversion of advanced, efficient motor technology into marketable products.

Typical applications for KEBA motor elements are often fast-moving applications such as turbo-blowers, turbo-compressors, vacuum pumps, tool spindles or turbo-generators.

Your benefits

- Performance of up to 300 kW

- Rotation speeds of up to 100,000 min-1

- Highly compact design

- Minor rotor losses

- Air- or water-cooled

- Application-specific rotor and stator design

- Optional: fully sealed versions for good thermal connection and corrosion protection

Pitch motors

For demanding applications in wind power plants

The pitch motors are adapted to the demanding operation in wind turbine installations and have been tested under extreme climatic conditions. The most notable features of the AC synchronous motors are their high power density and field-dampening abilities.

Your benefits

- Suitable for onshore and offshore applications thanks to corrosion protection class C5-M High, special interior coating and Gore-Tex membrane

- Long service life and reduced maintenance requirements thanks to integrated wear-free permanent magnet brake and robust resolver

Your benefits

Customized motors

To implement the required design, it is necessary to design motors that meet different requirements regarding construction type, version, rotation speed and performance. KEBA offers a wide range of compact synchronous and asynchronous motors. It goes without saying that coil configuration, case and bearings can be customized depending on the conditions in question.

Maximum performance with minimum investment

The mechatronics system approach makes it possible to optimize all components of the powertrain. You can operate your machines at maximum efficiency, minimizing purchasing and energy costs.

Features of our motor expertise

Top reliability

We value handshake quality – all parties involved should profit from a lasting and fair partnership.

Minor torque ripple

Despite the high performance density, we were able to reduce torque ripple (cogging) to a minimum – making the motor suitable for applications with high synchronism requirements.

High overload capacity

Our servo motors offer drive unit solutions for complex applications that can handle overloads.

High flexibility

Depending on the application, the range of options makes it possible to customize the motors for the specific requirements of each individual application.

Products

HMI - Human Machine Interface

Operating and monitoring: unique selection of mobile and stationary operating devices

Controls

Whether machine automation, robotics or wind energy: the perfect controller for every requirement in the range

I/O-Modules

KeConnect C5 I/O modules: optimum ratio of functionality to volume

Safety Technology

Safe operation according to all standards and guidelines: maximum safety for man and machine

Servo Controllers

Servocontrollers for high-performance and standard applications

Spindles

Precision spindles with roller bearings or magnetic bearings

Magnetic bearings

Wear and maintenance-free magnetic bearings thanks to non-contact technology

Software

Broad-spectrum of intelligent future-proof technology and software solutions

KeTop

Mobile handheld terminal