Standard Access to the Variables of a CODESYS PLC

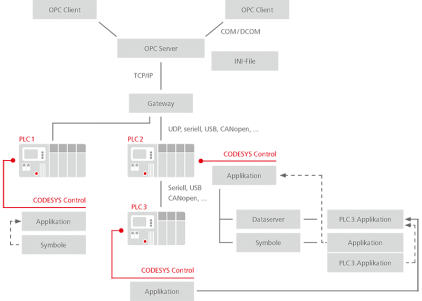

OPC (Open Platform Communications) is a standard interface which provides access to the data of an automation process. Main task of the CODESYS OPC Server is the exchange of data (read / write) with the controller for example for visualizations or for process data logging programs. The CODESYS OPC Server is an additional Microsoft Windows program that is included in the setup of the IEC 61131-3 Development System CODESYS. To use it, licensing is required: Either via a USB dongle (CODESYS Key) or a so-called SoftContainer on the PC running the CODESYS OPC Server.

Supported specifications

- OPC Common Definitions and Interfaces Version 1.0

- Data Access Custom Interface Standard Version 1.0a

- Data Access Custom Interface Standard Version 2.05A

- Data Access Custom Interface Standard Version 3.0

- Data Access Automation Interface Standard Version 2.02

- Alarms and Events Interface Version 1.10

- Hierarchical browsing of variables supported

The CODESYS OPC Server

- is part of the standard setup of the CODESYS Development System but requires a USB dongle license for usage

- comprises the server, a server configurator and a logger (for debugging)

- requires a symbol configuration in CODESYS with the data to be exported

- can be connected to controllers programmable with CODESYS V3 or CODESYS V2.3

- is certified by the OPC Foundation

Features and Functionality of the CODESYS OPC Server

- Automatic start upon establishment of a client connection

- Automatic trigger when a data value or a data status changes (OPC items)

- Browsing the variable list (item pool or address space)

- Managing the items in the data cache

- Direct access to items in the controller possible (without cache)

- Organization of the items in groups (private or public)

- Optional integrated data logger for diagnostics

- Multi-client support and multi-PLC support

- OPC connection also possible to controllers with CODESYS V2.3

- Included in the setup of the IEC 61131-3 programming environment CODESYS Development System. Requires licensing via the CODESYS Store

Using the CODESYS OPC Server

- Development of the IEC 61131-3 project in CODESYS

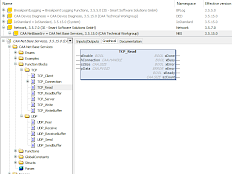

- Symbol configuration: Creation of the object in the application and selection of the variable values to be exported for the exchange of data via OPC

- Configuration of the CODESYS OPC Server for the connection to the desired controller using the configuration tool

- Login to the controller, download and execution of the PLC application

⇒ Automatic provision of the configured symbols via the CODESYS OPC Server - Start the OPC client and establish connection to the CODESYS OPC Server

⇒ Automatic start of the CODESYS OPC Server

⇒ Browse / use the item pool

Howtoget

The CODESYS OPC Server is available as standalone setup or as a part of the 32-bit setup of the CODESYS Development System.

The current version of the OPC Server Setup or the CODESYS Development System can be downloaded free of charge from the CODESYS Store after registration.

In order to use the OPC server, a license is required, which is stored on a USB-Dongle (CODESYS Key) or directly on the PC running the CODESYS OPC Server. Licenses and CODESYS Keys can be purchased at the CODESYS Store.

Products

CODESYS offers seamlessly integrated communication protocols for a wide variety of interfaces and requirements.

OPC UA

Standard Interface for Communication in Smart Factory and Industry 4.0 Systems

PLCHandler

Compact software interface (API) for easy access to the PLC variables in CODESYS controllers from external systems

BACnet

Configurator and protocol stack fully integrated in the IEC 61131-3 Development System

Serial interfaces

Although today almost every industrial controller has an Ethernet connection, serial interfaces are still installed in many industrial devices. This allows, for example, for the connection of appropriately equipped sensors and actuators or extensions.

Standard Ethernet

How does CODESYS communicate via Ethernet? How can I send and receive data from a CODESYS-compatible PLC via TCP or UDP? How can I realize data exchange from the PLC application?

Fieldbus systems and Industrial Ethernet

Sensors and actuators/actuators for processing control tasks can be separated from the controller via fieldbus and Ethernet systems with industrial communication protocols.

IIoT libraries

All IoT communication protocols can be implemented and used on different transmission media via software.

Other communication options

If a physical port is available on a controller, communication protocols can usually be implemented simply via software, either as part of the IEC 61131-3 control application or as separate library modules. Data exchange is performed by explicitly calling functions or function blocks as part of the logic control.

Proprietary communication protocols

CODESYS supports the most common standard communication protocols for data exchange between controllers, such as OPC UA. In addition, Ethernet-based fieldbus systems such as PROFINET or EtherNet/IP™ make it easy to exchange data between controllers by implementing master and slave functions.