Integrated BACnet®/IP Support in CODESYS

BACnet is a standardized data communication protocol for building automation and building control networks (Building Automation and Control networks).

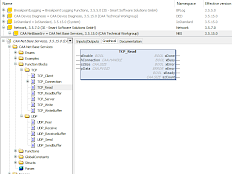

Scope of delivery

- an integrated configurator

- a protocol stack in the form of a CODESYS library

- a runtime system component

- device descriptions for BACnet servers, BACnet objects and BACnet clients

Available products and related datasheets:

- CODESYS BACnet SL

Functional Scope of the CODESYS BACnet Integration

- Defined set of BACnet objects, representing physical inputs, outputs and software objects

- Summary of BACnet objects in CODESYS in a BACnet server: Representing the functionality of a real device

- Characterization of objects by BACnet properties

- Orientation of BACnet integration in CODESYS to the AMEV AS-A and AS-B standards:

- Direct access of an IEC application to the properties of BACnet objects and the configuration parameters of a BACnet server

- Programming of BACnet clients: Access to BACnet functions in the BACnet network by BACnet services

- Applicative behavior of BACnet objects already pre-implemented, e.g. Property-Access, Calendar-Object, Schedule-Object, Who-Has, I-Am.

System Requirements

- Control with implemented CODESYS control runtime system

- Operating Systems: Microsoft Windows, Linux®

- CPU architecture: x86, Arm®(tested – more on request)

- Communication interface: Ethernet (TCP/IP)

Important communication protocols in building automation

Presentation of the most important communication protocols for building automation in part 3 of the video series"CODESYS in Building Automation".

Time codes for the concrete information about BACnet: Theory from 00:40 | Practice from 04:31

Further information on the use of CODESYS in building automation "

Reference information

- As System integrator or User in mechanical or plant engineering:

Use unit controllers or freely programmable controllers that are equipped with CODESYS BACnet support. Several million CODESYS-compatible individual devices and about 1,000 different device types from over 500 manufacturers offer you a large hardware selection for your automation projects. A selection of manufacturers of CODESYS-compatible devices can be found in CODESYS Inside. Alternatively, you can use the CODESYS Control SoftSPS systems from the CODESYS Store. CODESYS BACnet can be licensed as an additional option for some of these systems and can then be used immediately. - As Manufacturer of programmable devices / building controllers or aggregates for building automation:

Implement the CODESYS BACnet support on your hardware. To do this, purchase the CODESYS Runtime Toolkit with CODESYS BACnet. Alternatively, you can enable the option of single licensing (SL) on your devices. This allows the customers of their devices to license CODESYS BACnet for their application themselves, if necessary. - Advice, quotation and further information by info@emea.com.tr

Products

CODESYS offers seamlessly integrated communication protocols for a wide variety of interfaces and requirements.

OPC Server

Standard Interface to access the IEC 61131-3 process data of a controller via Open Platform Communications.

OPC UA

Standard Interface for Communication in Smart Factory and Industry 4.0 Systems

PLCHandler

Compact software interface (API) for easy access to the PLC variables in CODESYS controllers from external systems

Serial interfaces

Although today almost every industrial controller has an Ethernet connection, serial interfaces are still installed in many industrial devices. This allows, for example, for the connection of appropriately equipped sensors and actuators or extensions.

Standard Ethernet

How does CODESYS communicate via Ethernet? How can I send and receive data from a CODESYS-compatible PLC via TCP or UDP? How can I realize data exchange from the PLC application?

Fieldbus systems and Industrial Ethernet

Sensors and actuators/actuators for processing control tasks can be separated from the controller via fieldbus and Ethernet systems with industrial communication protocols.

IIoT libraries

All IoT communication protocols can be implemented and used on different transmission media via software.

Other communication options

If a physical port is available on a controller, communication protocols can usually be implemented simply via software, either as part of the IEC 61131-3 control application or as separate library modules. Data exchange is performed by explicitly calling functions or function blocks as part of the logic control.

Proprietary communication protocols

CODESYS supports the most common standard communication protocols for data exchange between controllers, such as OPC UA. In addition, Ethernet-based fieldbus systems such as PROFINET or EtherNet/IP™ make it easy to exchange data between controllers by implementing master and slave functions.