This makes it easy to implement virtual controls equipped with all the available CODESYS features and programmable with the CODESYS Development System in the IEC 61131-3 languages.

CODESYS Virtual Control SL is silver winner in the "Product of the Year 2023" voting

CODESYS Virtual Control takes second place in the category "Control" of the "Product of the Year 2023" voting.

We are very excited about this award would like to thank all readers of the trade journal Computer&Automation for their vote!

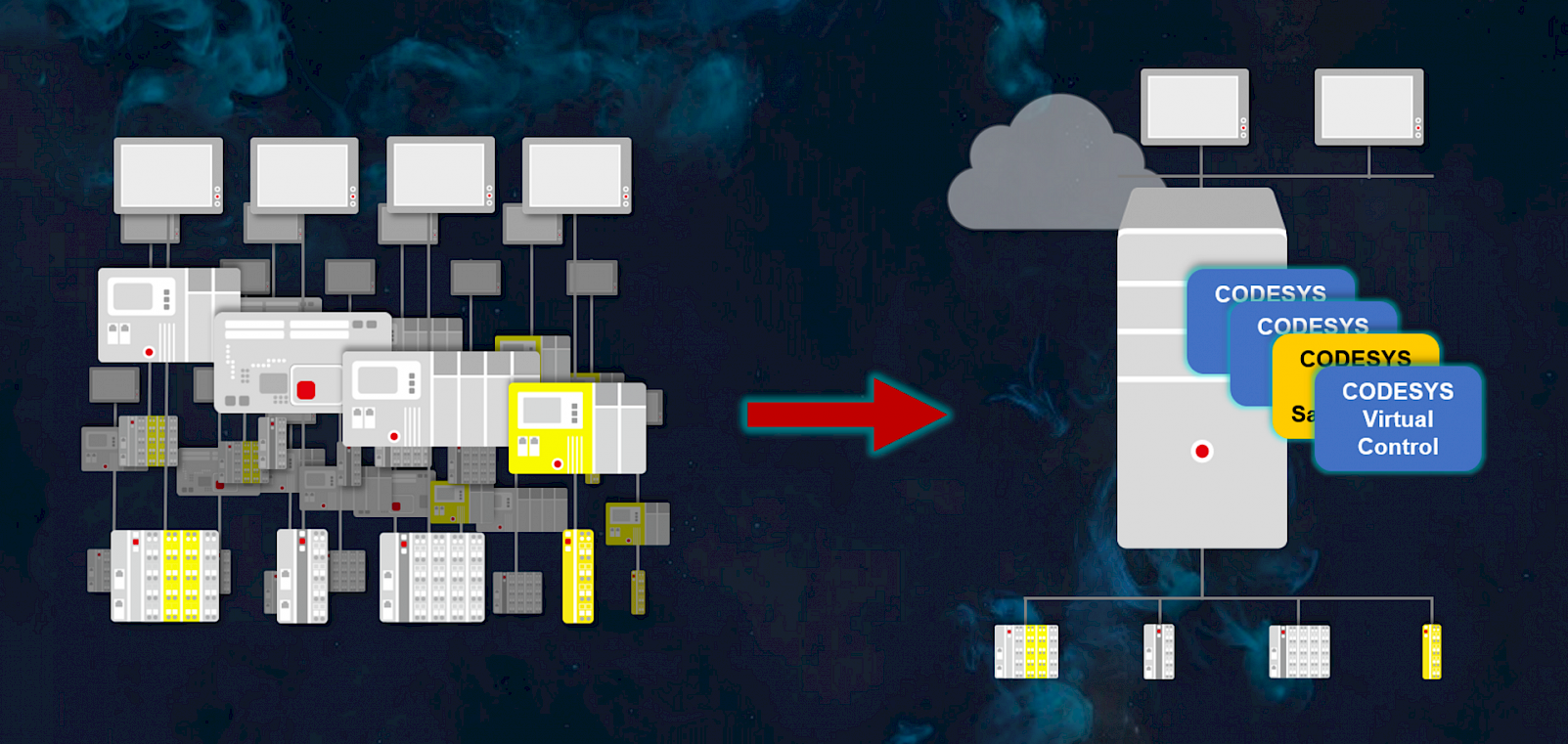

CODESYS Virtual Control lets you transform any modern system into an industrial controller - from small, dedicated ARM devices to IT farms. Completely independent of the hardware substructure.

Based on container structures, this new SoftPLC generation allows scalability in the number and performance of control instances and access to the field level via VLAN.

The advantages: Hardware independence as well as cost savings in procurement and maintenance.

Device Manufacturers

can offer images / configurations for CODESYS Virtual Control SL on their computers and industrial devices. This gives their customers, the users of automation systems, maximum freedom in the development of control applications which they can then, for example, organize in separate "micro-services".

CODESYS Users

can choose any computer architecture, such as industrial devices, servers, or cloud platforms to deploy or orchestrate CODESYS Virtual Control SL. In this way, they can implement exactly those virtual controllers they need for their application. The performance can also be scaled precisely. All control instances can be orchestrated via Linux commands or scripts, with appropriate tools (e.g. Kubernetes, Open Shift) or directly from the CODESYS Automation Server (in preparation). Access to field level is provided by high-performance virtual LAN, which is also available in all industrial devices.

Advantages of virtual control systems compared to classic PLCs:

- Enormous cost savings in hardware procurement, wiring, operation, and maintenance

- Machine and plant operators can provide and manage hardware platform themselves.

- Independence from hardware and hardware manufacturers

- Easy scaling through dynamic creation of control instances and the ability to expand hardware independently from software

- Security by design by distributing tasks to several independent control instances with powerful intercommunication

- Interoperability with other services ("micro services")

- Simplified rollout of security updates

- Central maintenance and care of virtual controls with the technologies and convenience of IT systems, including application updates

Curious?

Soon you will be able to test the Virtual Control yourself!

CODESYS Virtual Control SL Additional Files

Products

IEC 61131-3 controllers converted from any kind of intelligent device – by means of the adaptable CODESYS Control runtime system.

Runtime Toolkit

SDK for the implementation of industrial IEC 61131-3 controllers with a customized PLC runtime system programmable with CODESYS

Control

CODESYS Control is the corresponding runtime system to the CODESYS Development System.

PLCHandler

Compact software interface (API) for easy access to the PLC variables in CODESYS controllers from external systems

OPC Server

Standard Interface to access the IEC 61131-3 process data of a controller via Open Platform Communications.

OPC UA

Standard Interface for Communication in Smart Factory and Industry 4.0 Systems

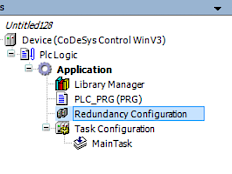

Redundancy Toolkit

Two Industrial IEC 61131-3 Controllers for one Single Application make the Application Fail Safe

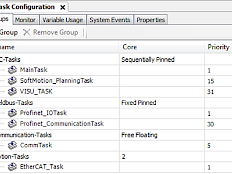

Multicore

Add-on component for standard devices with Symmetric Multicore Processing (SMP) support

![Virtual controllers [▶ 57:27] / Advantages and technical possibilities | ASE Congress 2022](https://i.ytimg.com/vi/IaeEuuJFrqY/0.jpg)